About our Tooling

Skarpaz blades are made with state of the art manufacturing equipment and production techniques using the finest saw material available. All Skarpaz blades feature the following qualities.

Laser cut saw bodies designed on an in-house computer aided design system cut from world class European alloy tool steel.

European C-3, sub micron corrosion resistant, or specialty grades for maximum edge and tool life.

Every saw plate is surface groungd for an exceptionally flat plate.

Every blade is individually roll and hammer tensioned by skilled hammer smiths.

Tri-Metal brazing of carbide tips on fully automated induction brazing machines.

Honed arbor holes to H-7 tolerance to ensure precise arbor fit.

Precision sharpening on automatic CNC machines ensuring accurate and consistent cutting angles.

| Hook + Tooth Style | General Application | |

|---|---|---|

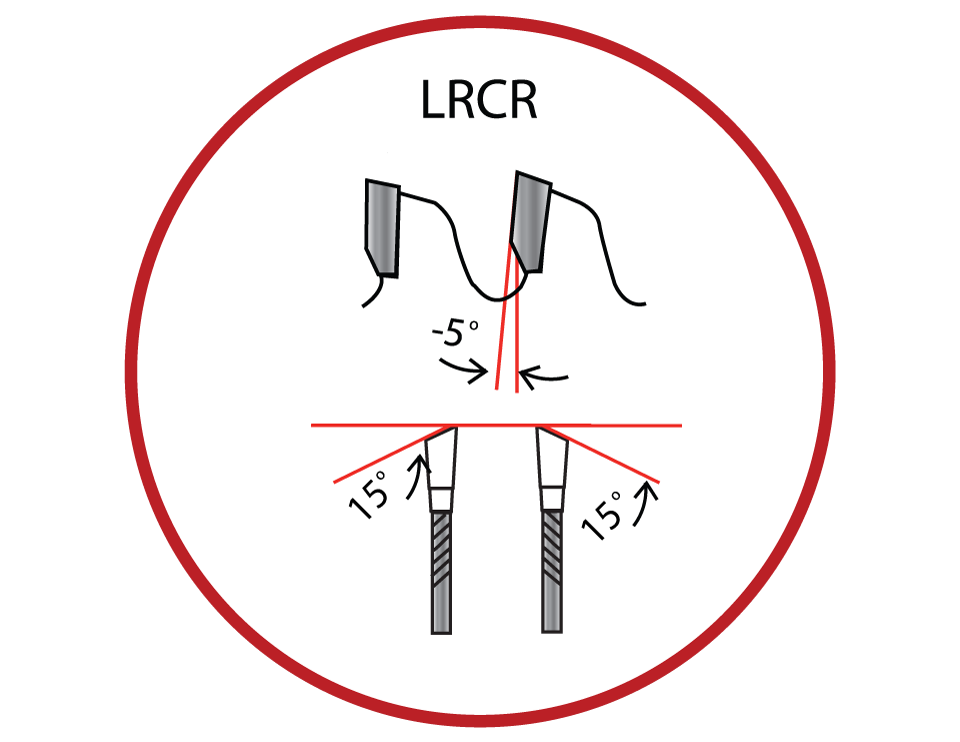

| LRCR: -5 degree hook + 30 degree top bevel |  | Double sided laminates |

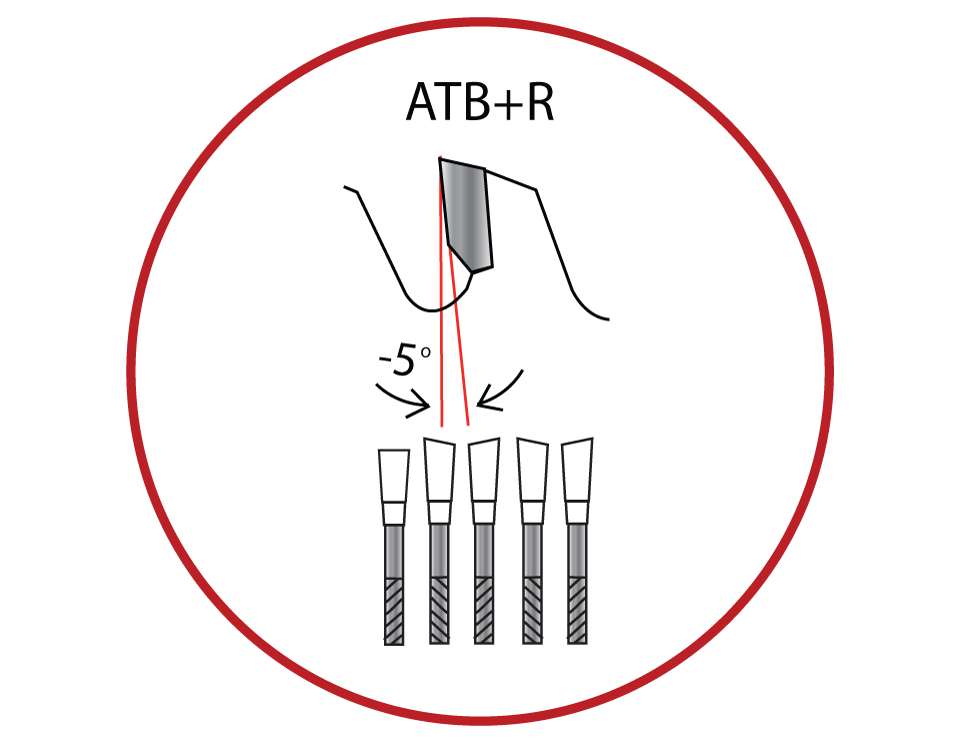

| ATB + R: 0 to -2 hook + alternate top bevel + raker tooth |  | Mitering picture frame moldings |

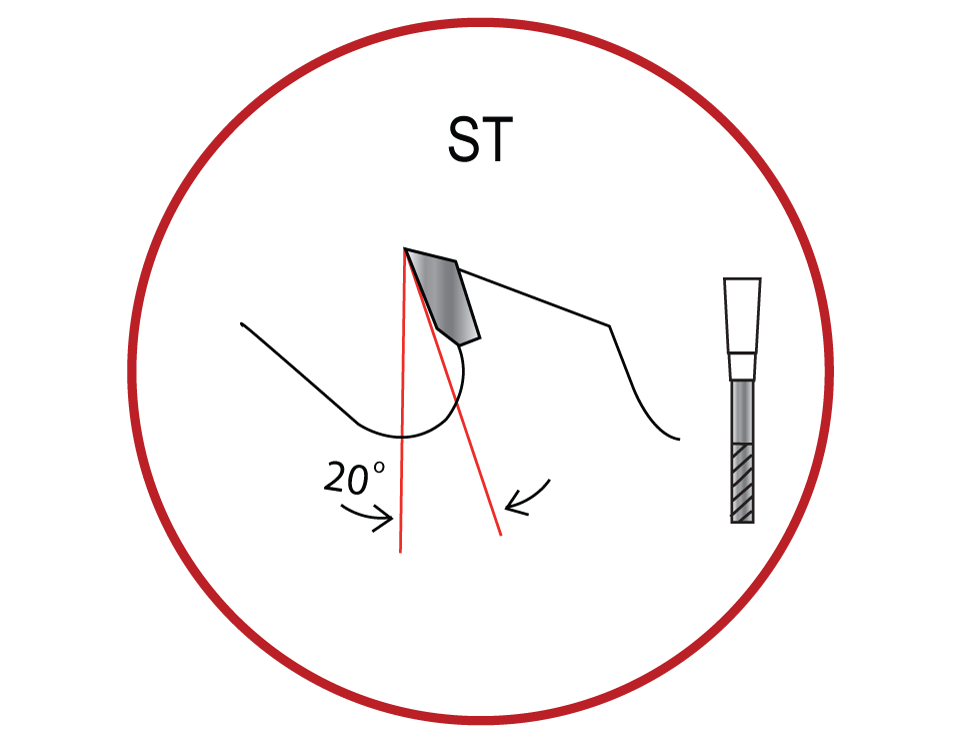

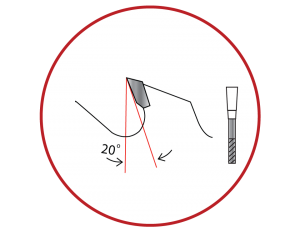

| ST: 20 degree hook + square top |  | Rip cuts in solid wood |

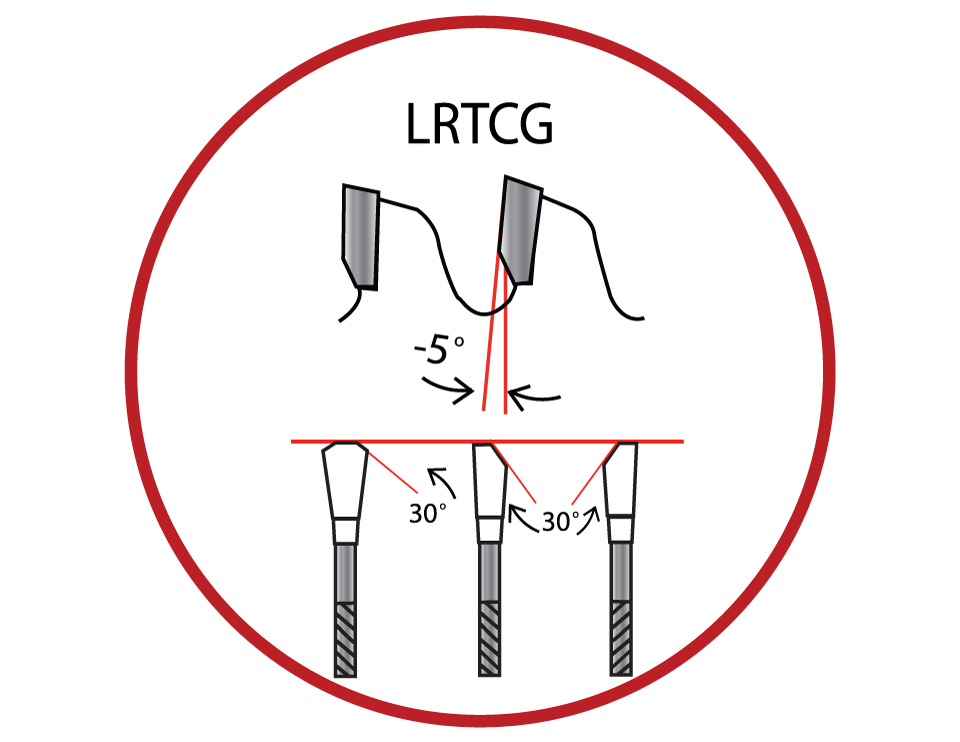

| LRTCG: 0 to -5 hook + three alternately chamfered teeth |  | Non ferrous metal |

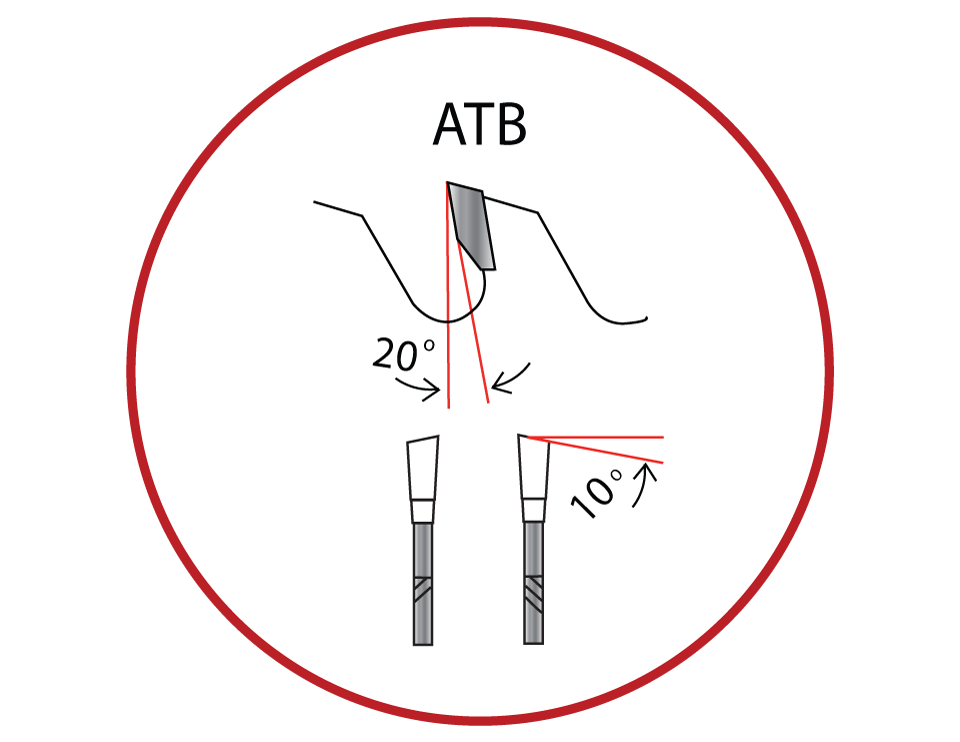

| ATB: -5 to 20 hook + alternate top bevels |  | Rip and cross cuts in solid wood |

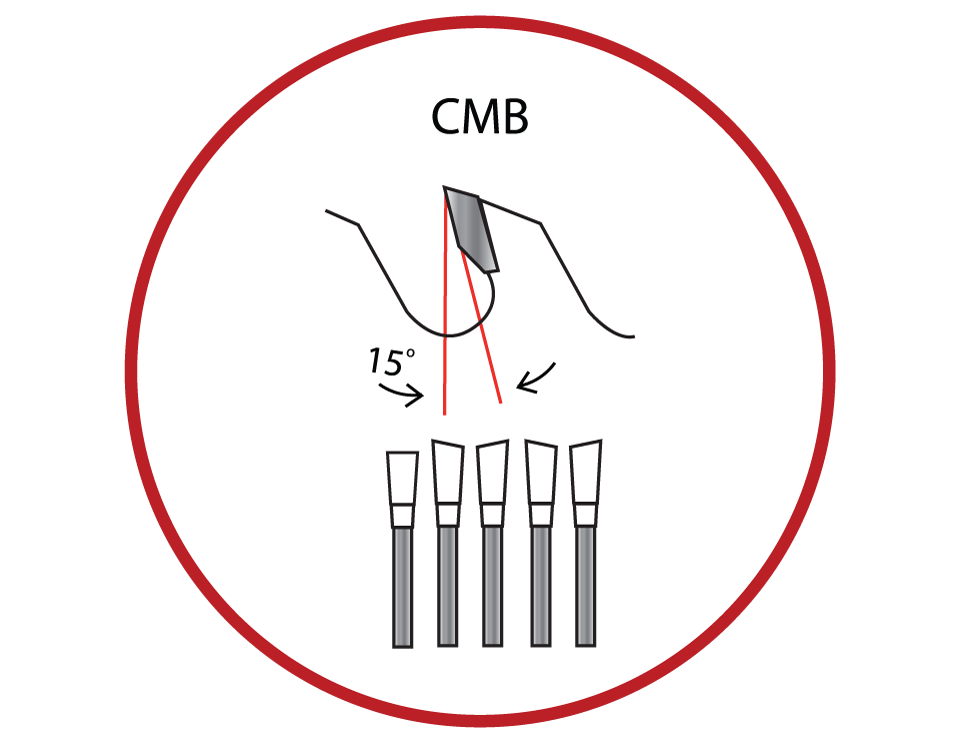

| CMB: 15 degree hook +alternate top bevels + raker tooth |  | Rip and cross cuts in solid wood |

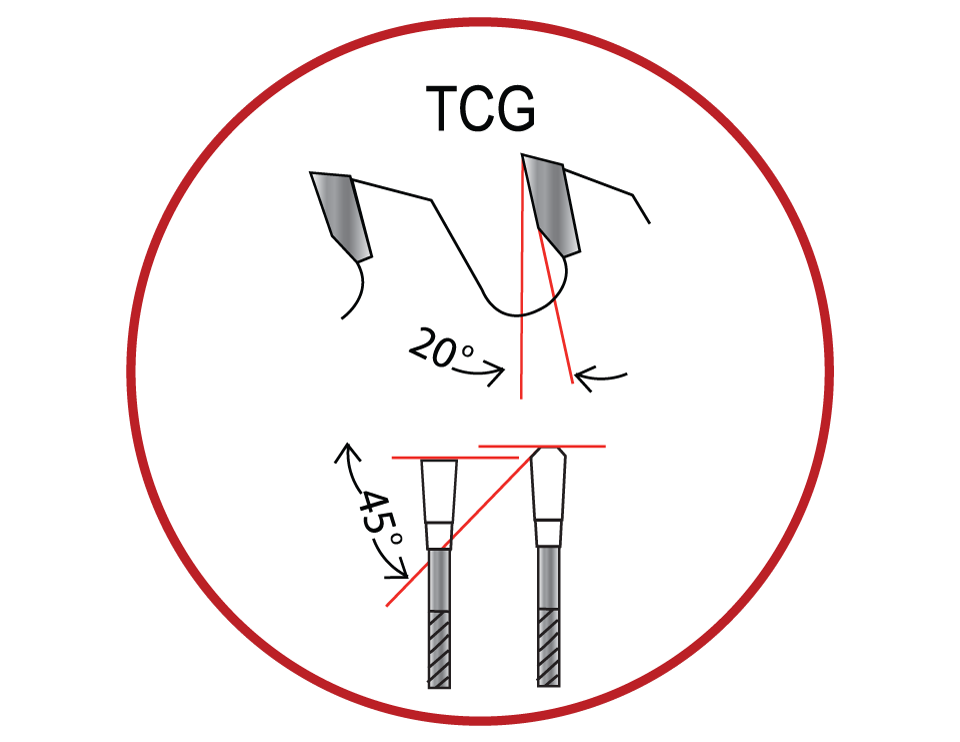

| TCG: -5 hook to 20 hook + triple chip grind |  | Non ferrous, plastics, laminates, hardwoods |

Hook Angles

For blades to achieve their optimum performance, the appropriate hook angle and tooth grind must be considered. In the following pages, hook angle and tooth style will be listed together