Technical Info

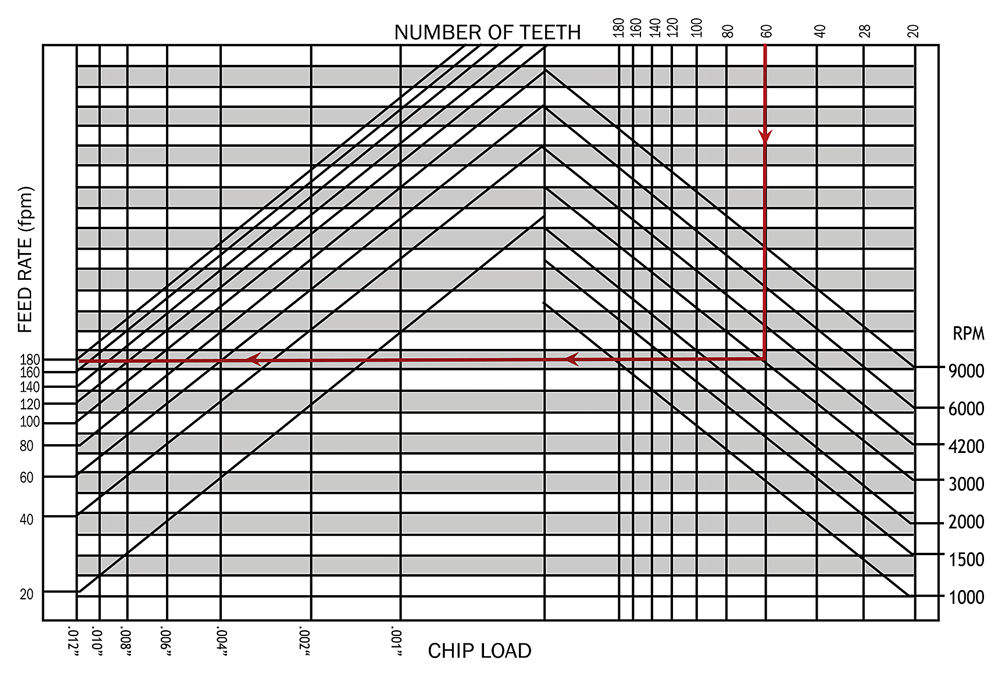

Chip Load Per Tooth

| Recommended Chiploads | Min | Max |

|---|---|---|

| Along grain | .008" | .035" |

| Cross grain | .004" | .008" |

| Hardwood | .002" | .006" |

| Chipboard | .004" | .010" |

| Veneered panels | .001" | .004" |

| Plastic laminated panels | .001" | .002" |

| Non Ferrous metals | .001" | .003" |

For instance: A 60 tooth saw rotating at 3000 rpm with a feed rate of 80 fpm will have a chipload of .0053″ Or to calculate chip load values, use the following formula: Chipload = 12 x feed per minute/RPM x number of teeth

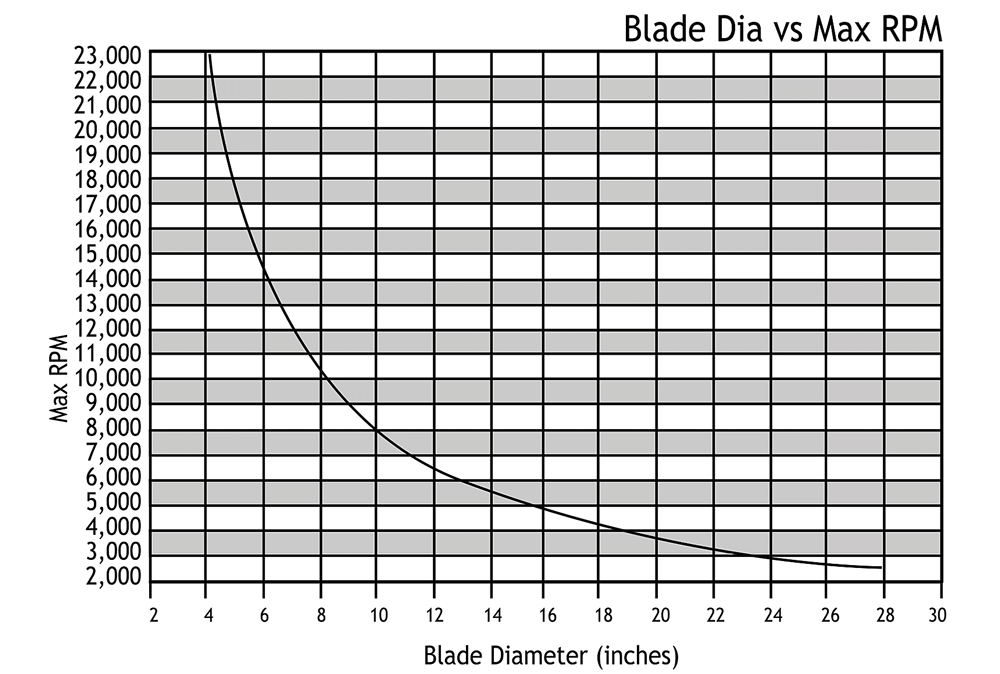

Blades Max. RPM in Relation Diameter

| Blade Dia | Max RPM | |

|---|---|---|

| Inches | MM | |

| 3 | 80 | 22,900 |

| 4 | 100 | 22,600 |

| 5 | 125 | 18,300 |

| 5.5 | 140 | 16,300 |

| 6 | 150 | 14,000 |

| 7 | 175 | 13,00 |

| 8 | 200 | 11,400 |

| 9 | 230 | 10,600 |

| 10 | 250 | 9,100 |

| 12 | 300 | 7,550 |

| 14 | 350 | 5,250 |

| 16 | 400 | 4,500 |

| 18 | 450 | 4,000 |

| 20 | 500 | 3,500 |

| 22 | 550 | 3,000 |

| 24 | 600 | 2,750 |

| 26 | 650 | 2,700 |

| 28 | 700 | 2,500 |